Your interface to the shop floor

The IKOffice software is a leader in the interaction of machine data and graphical capacity planning and thus decisive on the way to digitization and 'Industry 4.0' for the tool and mold making industry. Machine data acquisition creates the interface between the machines and the planning, control and analysis databases. The machine data and parameters can be transferred directly from the machine control to the systems. Alternatively, data can also be recorded by a control-independent sensor system directly on the machine, or manually. The received messages can additionally and online show the current state of production and ensure the traceability of the machining operations.

Industry 4.0 & Digitization

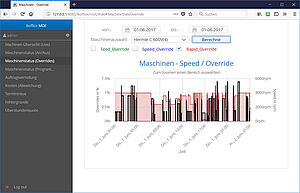

Visualization and dialog on all devices, objective measurement and monitoring system for plant runtimes, process and machine parameters, open to the integration of existing systems, ptimization of machine running times, evaluation of machine downtimes, captures machine and process data across systems

Machine Connection

Network connection, communication protocols, comprehensive machine/process data acquisition (MDE) in real time, notification of machine malfunctions via SMS or e-mail, machine condition, objective measurement and monitoring system for plant runtimes, process and machine parameters

Time logging

Dialogue masks, PDA, personnel time logging and manual machine time logging, capacity

Tool Documentation

Manage, view and archive, live machine overview, costs, tool cv, tool warehouse

Paperless Workshop

Digital PTR, providing digital data for a continuous improvement process, objective recording of processing times per component, shop floor visualization

Additional features

- Analysis of manufacturing processes and productivity

- Number of parts

- Running time (e.g.: of main spindle and feed axes)

- Availability and reliability

- Energy consumption (switch-on and switch-off times)

- Can be used independently of the respective machine & control model

Frequently asked questions about LivingMES

The software created by IKOffice provides the complete solution for all conceivable business transactions. Nevertheless, the specifics of your company can be realized in individual adaptations. Our software is adapted together with you to the conditions on site, without you losing the connection to the base and thus the ability to update.

Our server system is delivered as a virtual machine based on a Debian Linux. Of course, it can also be installed directly on a (hardware) server, i.e. without a virtualization host. The client is optimized for Windows, but also runs just as performant natively under Linux and uses GTK 3 there. The layout is a bit different in some masks, but identical in function.

The use of machine data can be seen as an essential factor for quality assurance and performance improvement in production and thus efficiently increase the competitiveness of a company. IKOffice LivingMES is scalable as required and specializes in tool and die making, with its traditionally mixed machinery. With IKOffice LivingMES it is possible to obtain detailed and complete evaluations/documentation of the utilization, productivity, quality and runtime of manufacturing processes. Errors, inaccuracies and the effort of manual bookings are avoided.

The maintenance or service contract ensures the readiness, up-to-dateness and security of your system and is a mandatory component during the entire use of your software. It includes all updates as well as telephone help and support (24h ticket system) for your employees. With about 7-12% of the total amount per year, we have created one of the most affordable and at the same time most comprehensive service in this industry.

Depending on the type of use, IKOffice can connect via interfaces to surrounding ERP systems such as SAP, Navision, Dynamics, WinCarat, AS400 and many more. We also successfully realize the transfer to financial accounting systems such as DATEV, FibuNet, Simba, etc.. Furthermore, connections exist, for example, to time recording systems such as ZEUS, AIDA, ATOSS or bedatime and control stations such as ProSeS or the ARBURG master computer system (ALS), as well as to various QA systems.

However, the exact method of transferring and accepting data is always an individual definition, which is agreed in preceding workshops. As an example, the integration is shown graphically in our flow chart.

IKOffice LivingMES supports the digitalization of your workshops. IKOffice MoldManager is aimed at the project-based individual manufacturer, as found in tool, mold, model, fixture, machine and plant construction, and our IKOffice LivingERP is the article-based ERP system for series production.

The systems unfold their full strength in the seamless interaction between product idea, toolmaking and series production