Stand-alone tool making (5 to 500 employees):

Do you want to get away from isolated applications? Do you want to better structure and professionally organize your own processes in the commercial area and in production? Then opt for our complete solution, IKOffice MoldManager, and make your workflows much leaner. Our software is clear, informal and fast in the administrative work around your order and projects. Specially developed for the needs of tool and mold making, plastics technology, stamping technology, forming technology and die casting technology.

In its basic version, IKOffice MoldManager offers everything a classic tool or mold maker needs in terms of support in his daily work. In addition to commercial tasks such as creating and tracking quotations, creating orders and generating delivery bills and invoices, our software also plans the most important workshop processes. We are constantly expanding the range of functions of our software, for a modern and future-proof system incl. all-round service.

Create quotes quickly and securely

Quotation templates allow you to quickly and securely process the inquiries you receive. Comparative offers are available to you, which also serve to determine the price. Adjustable text modules, images and your own design create an attractive offer, which is available at any time for follow-up in the resubmission.

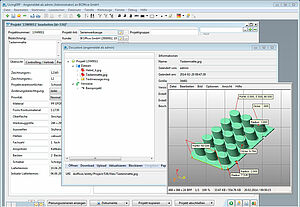

Practical planning

IKOffice MoldManager enables planning that meets the needs of even small companies in the industry. Unnecessary planning effort due to isolated applications is prevented and the ever more rapidly changing requirements of customers are mapped for you quickly, clearly and in a structured manner in our system. Thus, all process participants have an overview in a comprehensible and intuitive system. The IKOffice MoldManager offers everything that a "classic" company in tool or mold making needs in terms of support.

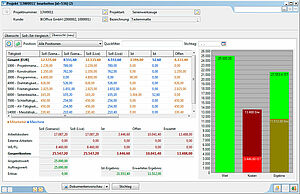

Control and information

Has the project already been processed? Have all goods been ordered yet? Was our last project calculated correctly? What are the external costs? What can be outsourced? Are there any changes during the construction phase? Do our costs remain within the contract value? IKOffice MoldManager answers all these questions and many more. The integrated document management makes it easier for you to assign all information to your project.

Capacity planning

Scenarios, rough planning and detailed planning against limited

Tool calculation

Similarity comparisons and calculation wizards

Time recording

Personnel and machine time, multi-machine connection

Project Management

Task, status and deadline management

Document Management

File storage and automatic keywording

Tool maintenance

Life cycle, maintenance planning and documentation

Additional features

- Copy feature

- Enquiry management

- Importing parts lists

- Performance monitoring

- Quotation analysis

- Quotation and document generation

- Quotation tracking

- Storage

- Supplier interfaces

- Versioning

- Work scheduling

- Workload overview

Frequently Asked Questions about the MoldManager

IKOffice uses the Java Connector (JCo) provided and certified by SAP itself. Accesses via this interface do not require external certification, since all accesses are made via standard BAPIs and are thus validated by SAP itself - according to the authorization assigned to the user used. This approach can therefore not lead to problems such as loss of warranty on the part of SAP. The design and scope of the data exchange is defined individually.

Our server system is delivered as a virtual machine based on a Debian Linux. It can also be installed directly on a (hardware) server, i.e. without a virtualization host. The client is optimized for Windows, but also runs just as performant natively under Linux and uses GTK 3 there. The layout is a bit different in some masks, but identical in function.

IKOffice MoldManager is the complete solution for every tool, mold, model, fixture, machine and plant manufacturer. It is aimed at small and medium-sized companies as well as the tool and die departments of large corporations. It is completely internationalized and designed for the parallel production of hundreds of projects.

As a rule, the process is completed after 4-8 months. The chart Introduction visualizes the main milestones of the introduction.

The costs for the IKOffice MoldManager are composed as follows:

- A basic license (one-time at the time of purchase)

- Number of user licenses (rule of thumb: 2 per 10 or more employees in the WZB)

- Introduction package (definition of interfaces and processes, rule of thumb: 1 package per 20 employees in the WZB)

- Training package (rule of thumb: 1 per 5 users)

- Annual maintenance costs (approx. 7-12 % of the total amount)

IKOffice MoldManager offers the complete package for tool and mold making and includes planning software that directly addresses the needs prevailing on site. Using a simple traffic light system, it informs planners, managers and controllers about bottlenecks in personnel or machinery. Optimization assistants help to avoid bottlenecks, but also to detect free spaces. The unique simulation planning enables the simulation of any planning scenarios and the transfer to the live environment. Historical data from the automated post-calculation is available at the push of a button.

IKOffice MoldManager provides support for preliminary costing, planning down to component level (if required), parts list import including all routings and material requirements, task management, capacity planning of employees and machines, tool life cycle and much more, all in an easy and intuitive system in which you will find your way around straight away.

Yes, IKOffice MoldManager can support all business transactions from customer inquiry to invoice. In terms of scope and function, IKOffice MoldManager is one of the leading ERP software for the tool and die industry.

There are deliberately only a few modules in IKOffice MoldManager. These include the extended time account management, the machine connection, the article calculation and a scan module. Our scan module, for incoming document assignment, is designed for fast, batch-based processing of incoming invoices. The assignment and recognition works via a document scanner, which generates PDF documents that are then run through our OCR recognition. The modules are offered separately if required. All other functions in IKOffice MoldManager are needed to run the scheduling of shop floor operations with the quality that IKOffice MoldManager is known for.

The software created by IKOffice provides the complete solution for all conceivable business transactions. Nevertheless, the specifics of your company can be realized in individual adaptations. Our software is adapted together with you to the conditions on site, without you losing the connection to the base and thus the ability to update.

The maintenance or service contract ensures the readiness, up-to-dateness and security of your system and is a mandatory component throughout the use of your software. It includes all updates as well as telephone help and support for your employees. We have created one of the most favorable and at the same time most extensive service contracts in this industry, with a yearly rate of approx. 7-12% of the total amount.

Yes, IKOffice MoldManager can be integrated into existing ERP or software environments. In this case, it seamlessly complements the existing structures.

IKOffice recommends the use of a virtual server, as we can provide pre-configured virtual machines for it. Of course, the IKOffice server can also be installed on a physical machine. If this should be the case, this will be coordinated with you individually.

The minimum requirements for the virtual server are as follows:

* Memory: min. 8GB RAM

* Processor: min. 1 CPU core

* Hard disk space: min. 20GB HDD

Recommended requirement:

* RAM: 12-16GB

* Processor: 2-4 CPU cores (from 10 concurrent users rather 4 cores)

* Processor frequency: >= 3Ghz CPU Freq. (IKOffice benefits from single thread performance)

* Hard disk space: >=50GB HDD (more if IKOffice document management is used)

Depending on the type of use, IKOffice can connect via interfaces to surrounding ERP systems such as SAP, Navision, Dynamics, WinCarat, AS400 and many more. We also successfully realize the transfer to financial accounting systems such as DATEV, FibuNet, Simba, etc.. Furthermore, connections exist, for example, to time recording systems such as ZEUS, AIDA, ATOSS or bedatime and control stations such as ProSeS or the ARBURG master computer system (ALS), as well as to various QA systems.

However, the exact method of transferring and accepting data is always an individual definition, which is agreed in preceding workshops. As an example, the integration is shown graphically in our flow chart.

IKOffice MoldManager is aimed at the project-based individual manufacturer, as found in tool, mold, model, fixture, machine and plant construction, and our IKOffice LivingERP is the article-based ERP system for series production. The IKOffice LivingMES supports the digitalization of your workshops.

The systems develop their full strength in the seamless interaction between product idea, toolmaking and series production.

The user licenses of the IKOffice software can be purchased as named or concurrent (also floating) licenses. While with Named licenses the users are defined by name, the number of Concurrent licenses only limits the number of any users. For further explanations, please refer to the License Explanations information sheet.

![[Translate to English:] Praxistaugliche Planung](/cms/fileadmin/_processed_/a/0/csm_MoldManager-Projektplanung_5618ea7aff.jpg)